Ionizor

- Converts Organic substances to ''Carbonaceous'' and further destruction to become “Ash”

- For Inorganic substances, there remain unchanged as ''Dry Products''

The application of IONIZOR are:

• Industrial Scheduled Waste

• Medical Hazardous Waste

• Domestic Waste

• Green Waste

Type of Wastes: Solid / Shredded Solids

Waste Compositions: Organic & Inorganic & Moisture

Remarks: Excessive moisture content may require pre- treatment in separate apparatus or further increase of fuel consumption

The unique process advantages of IONIZOR are:

• Non-human touch

• Environmental Friendly System Safe equipment

• Cost-Effective solution with ZERO fuel (energy) needed for process thermal treatment

• Only minimum fuel needed for complete combustion of Volatile Organic Carbon Gases (Syngas), Smokes & Odours

• Organic substances converted into Carbonaceous & further destructed into Ash

• Inorganic substances remain unchanged as “Dry Products” residues

• High organic substances reduction > 95% (weigh/volume)

• Low OPEX and FAST R.O.I

• Cleaner, easy handling of working environment and condition

• Industrial Scheduled Waste

• Medical Hazardous Waste

• Domestic Waste

• Green Waste

Type of Wastes: Solid / Shredded Solids

Waste Compositions: Organic & Inorganic & Moisture

Remarks: Excessive moisture content may require pre- treatment in separate apparatus or further increase of fuel consumption

The unique process advantages of IONIZOR are:

• Non-human touch

• Environmental Friendly System Safe equipment

• Cost-Effective solution with ZERO fuel (energy) needed for process thermal treatment

• Only minimum fuel needed for complete combustion of Volatile Organic Carbon Gases (Syngas), Smokes & Odours

• Organic substances converted into Carbonaceous & further destructed into Ash

• Inorganic substances remain unchanged as “Dry Products” residues

• High organic substances reduction > 95% (weigh/volume)

• Low OPEX and FAST R.O.I

• Cleaner, easy handling of working environment and condition

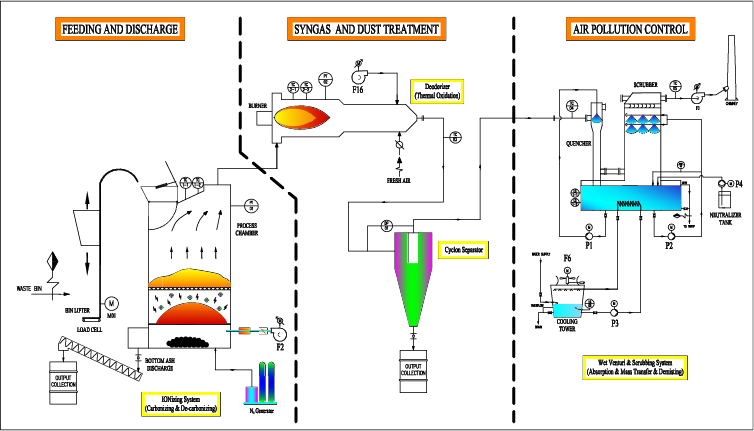

This technology adopts Environmental Friendly design, which utilizes:

• Oxygen-starved process condition to avoid formation of hazardous gases & self-burning

• Carbonization & De-carbonization process treatments in a fully enclosed chamber

• State of Art with complete range of Air Pollution Control System to effectively control and remove Fumes, Volatile Organic Carbon Gases (Syngas), Dust Particulates, Smokes, and Odours generation during process thermal treatment

• Fully Automatic & PLC Control

• Oxygen-starved process condition to avoid formation of hazardous gases & self-burning

• Carbonization & De-carbonization process treatments in a fully enclosed chamber

• State of Art with complete range of Air Pollution Control System to effectively control and remove Fumes, Volatile Organic Carbon Gases (Syngas), Dust Particulates, Smokes, and Odours generation during process thermal treatment

• Fully Automatic & PLC Control

Type of Wastes

Process Flow Diagram

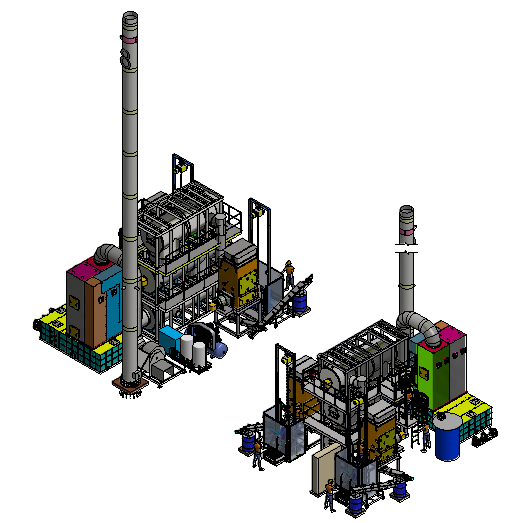

Pilot Unit

Air Emission

Discharging Ash

Pro-Batch System