Carbonator

- Converts Organic substances to ''Carbonaceous'' (Carbon/Char)

- For Inorganic substances, there remain unchanged as ''Dry Products''

The unique process advantages of Carbonator® are:

• It dries off or removes > 99% moisture/water content;

• Physically reduces, chemically breaks down and converts the organic substances into stable and odorless carbon/char;

• Leaves the inorganic substances unchanged as it is for recycling where applicable.

This technology adopts Environmental Friendly design, which utilizes:

• Indirect Heating (Indirect Thermal Desorption concept) of applying dry hot air where variable clean fossil fuels (Natural Gas/LPG/Diesel) heat sources can be used

• Isolated process treatment condition to achieve the Thermal Breaking point of various organic substances

• Low - Medium (250 ºC – 450 ºC) process treatment temperature

• Inert gas purging to promote Oxygen starved condition to eliminate formation of pollutant gases and self-burning

• It dries off or removes > 99% moisture/water content;

• Physically reduces, chemically breaks down and converts the organic substances into stable and odorless carbon/char;

• Leaves the inorganic substances unchanged as it is for recycling where applicable.

This technology adopts Environmental Friendly design, which utilizes:

• Indirect Heating (Indirect Thermal Desorption concept) of applying dry hot air where variable clean fossil fuels (Natural Gas/LPG/Diesel) heat sources can be used

• Isolated process treatment condition to achieve the Thermal Breaking point of various organic substances

• Low - Medium (250 ºC – 450 ºC) process treatment temperature

• Inert gas purging to promote Oxygen starved condition to eliminate formation of pollutant gases and self-burning

.png)

Process Thermal Treatment – Cross Section

.png)

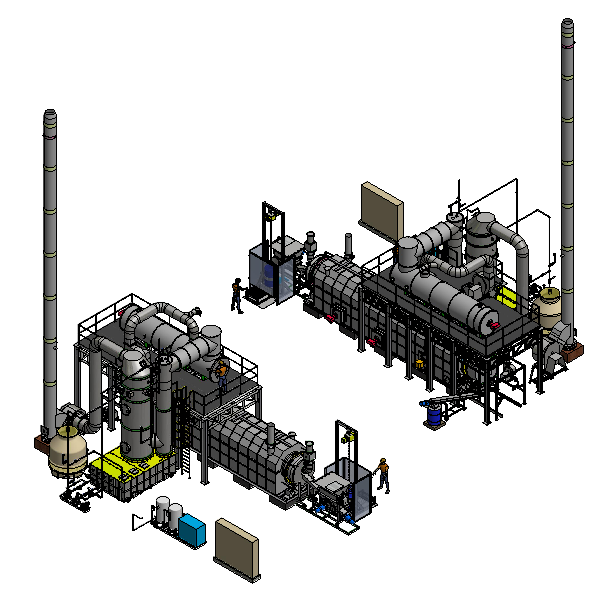

System Configuration

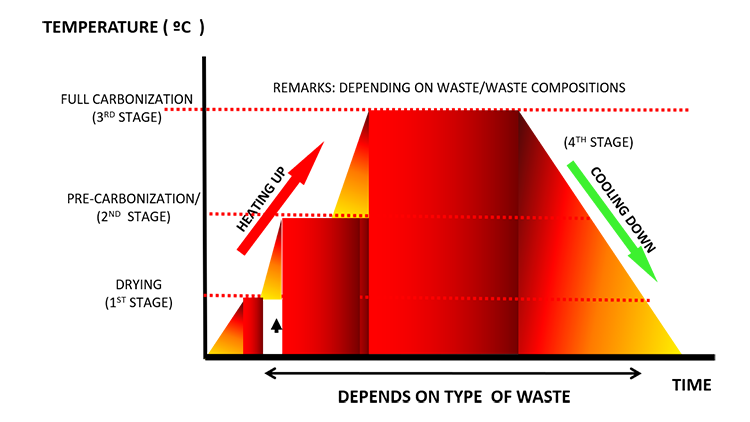

Process Cycles

Process Flow Diagram

Air Emission ''with'' & ''without'' Deodorizer System

Output discharge